Why Compatibility in Foam Pumps Matters

The Science Behind Foam Pump Functionality

Foam pumps are intriguing gizmos that are very alert to the behavior of air and liquid in order to make froth. These pumps use elaborate modes to add air to weak liquid solutions, including a mesh screen or aerator chamber and result in a rich frothy foam. This mixture is, in turn, determined by the interaction between air dynamics and liquid characteristics, to a great extent determined by the design of the foam pump. A well-engineered foam pump highlights the function of surfactants in high quality froth generation and guarantees that the froth is consistent and it is applied for the purpose as may be in foaming hand soaps or face wash.

The factors that effect foam quality are studied by examining the surfactants coupled with pump design. Surfactants are critical because they lower the surface tension, permitting the liquid to foam. Industry studies have indicated that certain formulations, when dispensed using properly designed foam pumps, will produce superior foam. Compliance with industry standards is more than selecting the correct surfactants; it also requires blending them into the right pump design to optimize air mixing and pressure control. This guarantees the provision of a foam already suitable for use, which increases the benefit to the consumer.

Risks of Ignoring Compatibility in Cosmetic Packaging

If compatibility between the foam pumps and product formulations is not addressed, pumping clystyle and uneven flow of foam is obtained. When selecting a pump, it’s important to match the viscosity and the composition of the liquid with the pump’s ability to also mix air and liquid. When this discrepancy is present, the performance of the foam pump is reduced and consumers are not satisfied with the product and/or it may fail to succeed as a product in the marketplace. Product recalls can disrupt cosmetic brands Real Life examples A quick search of product recalls and cosmetic brands in Australia found that many products were recalled by cosmetic companies, often for cosmetic symptoms that would be costly and easily prevented. Reports from industry have cited several reasons why foam pumps fail, highlighting the importance of formulating practices.

The consequences of not working with compatible cosmetic packaging are costly. In addition to the cost of product recalls, there is both the potential for squandering materials and for offending brand perception. Unsatisfied customers who are not able to rely on consistent foam can have a tarnishing impact on a brand and can potentially break consumer trust. Not to mention the cost and hassle of collecting the dumped item and handling consumer complaints. Developers must invest in testing and compatibly checking to stop these and preserve their market reputation as well.

Viscosity and Formula: Core Factors in Foam Pump Performance

How Product Thickness Affects Air-Liquid Mixing

Voilicity is critical when it comes to evaluating how well a Foam Pump mixes air and liquid to create diluted foam. Both factors depend on viscosity, the thickness of a product, which affects the air-liquid dynamics in a foam pump. Rheological measurements have also showed that thickening agents can impede mixing of air and liquid and thereby result in poor foam quality. For example, an article published in the Journal of Dispersion Science and Technology details that there is an idea viscosity range for adequate foaming and this is usually between 150-500cP for most personal care applications. Insustry guidelines will often reinforced this with references to where items such as facial cleansers and shampoos have the best performance at viscosities within these guidelines. Graphical elements may graphically illustrate the correlation between viscosity and foam quality highlighting the appropriate equilibrium for best foam creation.

Case Study: Foam Quality Failures Due to Formula Mismatches

There is a major setback for manufacturers when formulation and foam pump compatibility don’t match. Based on a case study, it was shown how a major skincare brand experienced quality foam failures because of a formula incompatibility. But the source of these problems are weak chemical reactions and pump designs that weren’t designed to handle a liquid with your formula’s viscosity. It was found by the study that the surfactants employed could not produce long-lasting foam with the existing configuration. Many a lesson is there for future projects. Thorough testing of new formulations, when new pumps are used, will prevent such mishaps. It also demonstrates the importance of involving engineers and chemists early in product development efforts to identify and resolve potential failures with respect to foam quality.

Material Compatibility Challenges in Foam Pump Design

Chemical Resistance Testing for Plastic Components

Testing for chemical resistance is essential in the design of foam pumps to guarantee the durability and life span of the parts. These tests can be used to characterize the response of materials to different cosmetic products and help the manufacturers to choose the appropriate materials. Immersion tests and SC-resistance exams are the most common methods, which mimic chemical long-duration contact. For example, failing to do this has resulted in product failures – such as dispensers cracking, which costs brands dearly in terms of refunds and damage to their reputation. A great example is Brand X that experienced customer wrath because of leaky pumps caused by their scrimping on chemical resistance tests.

Long-Term Degradation Risks with Reactive Formulas

Reactive formulations have proven to be particularly problematic over time, as they are capable long-term deleterious effect on foam pump materials. Compounds such as essential oils and alcohols are believed to slowly break down plastics and reduce their function, studies have found. Polycarbonate and some varieties of polyethylene are especially prone to this degradation. Manufacturers can use several techniques to mediate these risks. The life of the pump can be extended by employing barrier coatings and using more inert materials of construction such as PTFE. Further, periodic testing and design specific to formulas are ways to prevent this aging process, promoting continued good order and end user satisfaction.

Validating Compatibility Through Industry Testing Protocols

Accelerated Aging Tests for Packaging Integrity

Accelerated aging tests are critical for the assessment of long-term foam pump performance to maintain package integrity during the product lifetime. Through recreating the impact of time, temperature and environmental factors, these tests aid in the prediction of performances of the foam pump parts in their application field. Conventional standards, such as ASTM F1980 or ISO 11607, are based on these parameters, to guarantee that the ageing process is indeed reproduced. Manufacturers use these tests to evaluate product durability and determine the materials and designs that will better survive the conditions specified.

The knowledge of the influence of these tests enables to predict failure and finally to validate foam pump better. For instance, information collected from accelerated aging experiments can provide guidance in the design or material changes which will lead to product durability and customer satisfaction. If you can predict that, then you can adjust before you get all the shelf data and avoid risk and have a very dependable product that performs well over time in the market.

On-Site Performance Evaluations for Bulk Production

Local, one-on-one trials are necessary to assure equal production during bulk runs. These tests offer a real-time feedback of foam pumps, such as small defects, or any incompatibility, which would not be observed under laboratory conditions. Performing this type of test on the production floor allows manufacturers to adjust their process without having to send it to a lab, and likely reduce the production of faulty product, so each batch can meet the high quality standards set by consumer and regulators alike.

There assessments can go a long way to mitigating against expensive recalls or product failures. For example, feedback from on-site testing could indicate a problem with how the foam pump operates with a specific solution and changes can be made to rectify any potential incompatibilities. This forward-looking mindset ensure that products are constantly improved and better adapt to the market and the long term trust of consumer. With the knowledge gathered from such studies, it is possible for companies not only to optimize production steps, but to obtain a higher-quality, more reliable foam pump.

Optimizing Foam Pump Selection for Brand Success

Balancing Cost, Functionality, and Aesthetics

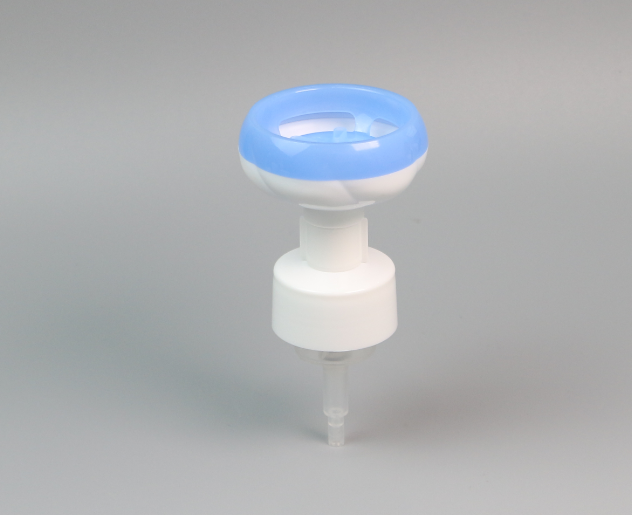

When choosing foam pumps, manufacturers need to weigh cost against function to find the most suitable option. The price of foam pump is possible to vary greatly depending on the material, design and technology. Cost effectiveness is important, but not at the expense of functionality for the user. For example, a trusting, reliable, and easy-to-use foam pump can help engage users while maintaining user satisfaction – a key factor in the development of brand loyalty. Aesthetic is also an important factor to consider when choosing a product. The appearance of a foam pump is important to the whole brand image, and naturally the better the look, the more likely is the ability to attract consumers. Using trending colors and unique shapes can help a brand stand out in a crowded market. Recent developments emphasise an increasing demand for superior quality foam pumps that combine both functionality with attractive design. Brands that recognize these dynamics, however, can choose carefully and can satisfy both their own craving for promotion and their budget.

Future-Proofing Packaging with Modular Foam Pump Systems

Modular foam pump systems are emerging as a fast lane for fast brands. These are flexible systems, both in design and in application, perfect for today's marketplace, which changes with consumer needs and environmental laws. "Brands can do this, for example, by selecting modular foam pumps to offer the flexibility of modifying parts to suit different formulations or for aesthetic requirements, without the need for re-design. This is important for ensuring your packaging is future proofed and on trend. Successful case studies show that brands using modular systems to respond more rapidly to market trends achieved increased agility and sustainability. With the industry swinging towards green alternatives, systems that are modular and can reduce waste, yet offers customisation, are believed to be a winner. Establishing these kind of systems further falls in line with new trends that are promoting sustainability and eco-friendly packaging, in turn becoming a significant contributing factor to brand competitiveness.

FAQ

Why is compatibility important in foam pumps?

Compatibility ensures that the foam pump and the product formula work together effectively, preventing issues like pump clogging and ensuring consistent foam delivery, which enhances consumer satisfaction.

How does viscosity affect foam pump performance?

Viscosity affects the air-liquid mixing dynamics in foam pumps. An optimal viscosity range ensures efficient foam production; too thick or too thin formulas can compromise foam quality.

What are some risks of ignoring formulation compatibility with foam pumps?

Ignoring compatibility can lead to pump failures, inconsistent foam quality, and costly product recalls, damaging brand reputation and consumer trust.

How can manufacturers ensure material compatibility in foam pumps?

Manufacturers conduct chemical resistance testing to assess how different components react with formulations, selecting materials that resist degradation over time.