How All-Plastic Trigger Sprayers Combat Packaging Waste

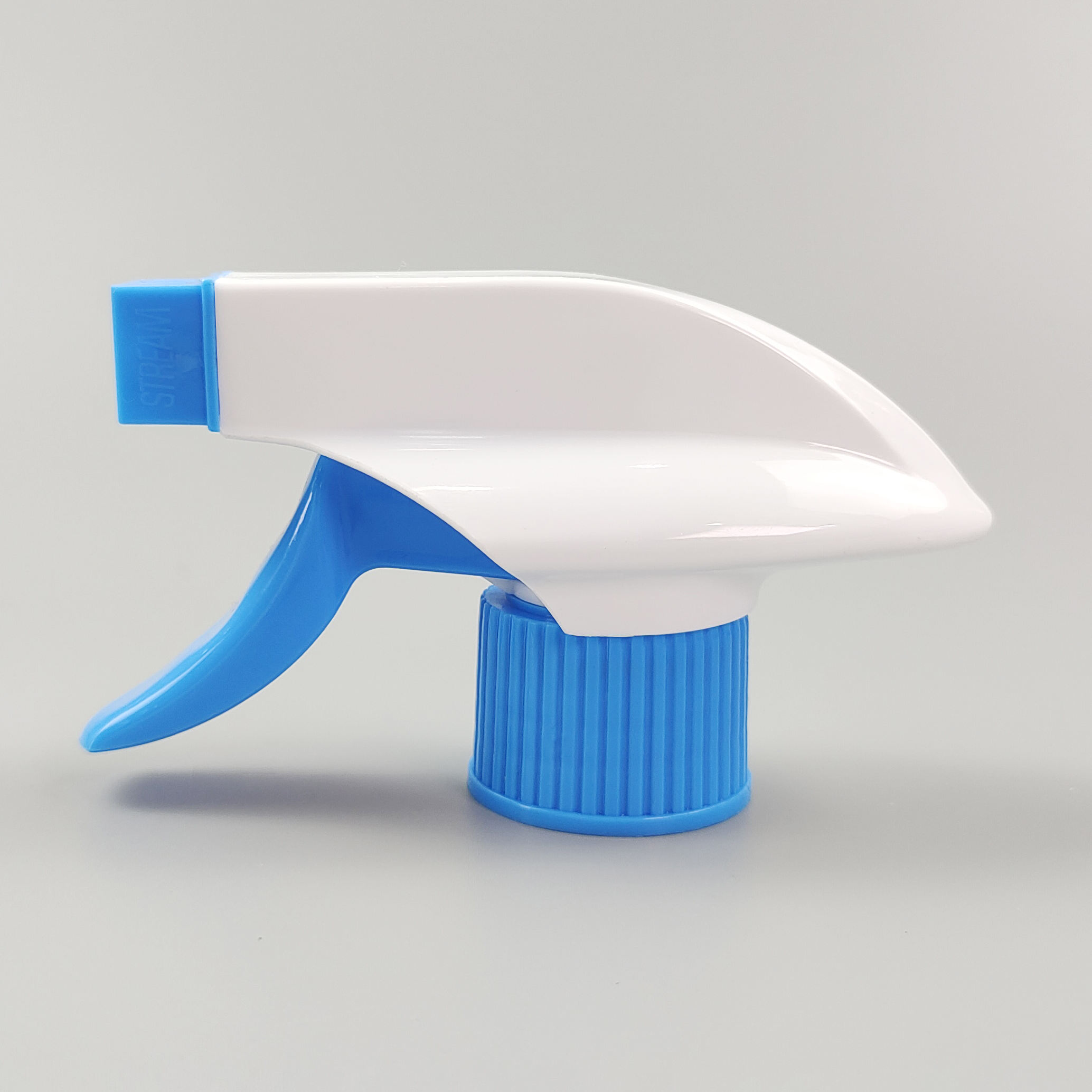

The Problem with Multi-Material Dispensing Systems

The recycling of such multi-material dispensing systems is generally problematic, given their complex design and construction including plastic, metal, etc. These hybrid material systems are difficult to recycle, resulting in recycling inefficiency. Some 91% of plastic is never recycled — most of which are mixed-material products, statistics reveal. As a result, many of these systems wind up in dumps, contributing to the ever-growing problem of plastic waste that plagues the planet. The cons perhaps outweigh the pros as separating and recycling separately each of these, adds to the cost of depositing waste and lessens the efficiency of recycling for a good cause.

Complete Recyclability of Mono-Material Designs

There is also a strong move towards mono-material constructions as these require only one type of plastic, and may show promise in terms of recyclability. This simplification greatly facilitates recycling, resulting in a much higher recovery rate. Research shows that using mono-material packaging can increase recyclability by up to 30%. With this recycling system, recycling quality is enhanced, as the risks of contamination found in mixed-material systems are removed. This trend to less complex packaging materials is pushing manufacturers to look for truly recyclable technologies with very positive environmental impact. With a focus on mono-material designs, businesses have the power to curb packaging waste and promote sustainable packaging options.

Environmental Advantages of Plastic-Only Construction

Eliminating Metal Components for Simplified Recycling

It is important to eliminate metallic parts in trigger sprayers to prevent contamination in when recycling. And when metal parts are mixed with plastic, they act as blockers to efficient recycling, thus discouraging recycling-friendly practices. Studies have shown that over 70% of consumers prefer packages which are easily recycled. Going for a plastic-only construction allows for streamlined recycling systems, and ultimately easier recycling and upcycling of the material into new product. Sprayers Completely Recyclable, Reduce Life-Cycle Carbon Footprint Manufacturers are able to produce sprayers with no negative impact on the recycling system by using these designs to create a more sustainable future for consumers as well as businesses.

Reducing Contamination in Recycling Streams

This plastic-only format is an important part of preventing contamination that disrupts how recycling facilities work. Studies have shown that addressing contamination could raise the quality of recycled plastics by 25 percent, making recycling more effective. Clear labelling, as well as adequate recycling information displayed in products, can raise consumer participation in recycling initiatives. Furthermore, it is important to educate consumers of the need for appropriate disposal which in turn helps to maintain cleaner recycling streams allowing precious materials to be diverted from refuse in the most efficient manner.

Lightweight Design's Role in Lowering Transport Emissions

The light weight of all-plastic designs is a key factor for lowering transportation cost as well as the corresponding carbon dioxide emissions. The numbers According to statistics, reducing product weight by 20% results in about 15% fewer energy consumption by every delivery. Al, for example, causes the weight saving of the two structures that are connected to the joint by the assembly lines that transports just about anything that saving costs a bomb. And with eco-measures moving the goalposts of sustainability metrics in favour of lightweight packaging, these designs represent a scaleable way of reducing emissions. In the end, companies can do their part to be environmentally green through the use of lighter weight alternatives and simultaneously save on transportation costs.

Key Industries Benefiting from Plastic Trigger Sprayers

Household Cleaning: Foam Pump Soap Applications

Plastic trigger sprayers are used widely in the household cleaning industry, consumers like it very much for the foaming soap. These foaming soap pump dispensers are a game changer in terms of the user experience, allowing you to obtain difficult-to-squirt, gunky pumps and the ability to get a precise consistency according to your personal taste. According to the industry information, consumers are increasingly interested in environmentally friendly products, and that’s why foam pump hand soaps are in high demand. In addition, being able to provide bespoke and adaptable design, brands can make their mark in this crowded marketplace attracting consumers seeking both form and function.

Personal Care: Cosmetic Mists and Lip Gloss Solutions

Plastic trigger sprayers are indispensable in the personal care sector, especially due to their usage in cosmetic mist and lip gloss products. Several companies are already transitioning to sustainable packaging, with reusable systems which appeal to the increasingly eco-minded consumers. The move to refilling options is also reinforcing brand loyalty, as consumers are more likely to back companies putting sustainability at the top of their agenda. Moreover, advancements in packaging design make it possible to have sleeker and sexier applications! This means that these products aren't only effective, but are also designed to catch your client's eye.

Agricultural Sprayers for Precision Chemical Delivery

Plastic trigger sprayers are known to be very beneficial in agriculture as they permit control of the application of the chemicals. These sprayers provide for controlled dispensing, thus reducing waste and contamination due to over-application. Statistics suggest that specific application methods could save farmers up to 30% on annual chemical expenses. On the other hand, the resistance to wear and tear and harsh chemicals makes the plastic sprayers ideal for the agricultural industry – which requires something solid and reliable.

Manufacturing Innovations Driving Sustainability

Bio-Based Polymers in Sprayer Production

The use of bio-based polymers in the sprayer manufacturing process is a great step towards sustainable practices with less reliance on fossil resources. Bio-based materials can reduce carbon footprints by as much as 50% during production, research has shown, indicating the positive impact bio-based materials have on the environment. Companies who embrace these advances prove great dedication to sustainability and thus cater to those eco-aware buyers who seek their designer goods eco-friendly. In addition, sources of bio-based materials are likely to increase, giving manufacturers additional eco-friendly alternatives to incorporate into their manufacturing operations.

Energy-Efficient Injection Molding Techniques

Energy saving technologies in injection molding have evolved, thus leading to energy saving in manufacturing and increased part productivity. Using the newest technology, it s aves up to 30% in energy consumption online play taking on other mold molding craft. This transition not only results in slowing the growth in greenhouse gas emissions, but it makes a manufacturing process more sustainable in general. When manufacturers implement these energy-saving technologies the result is frequently an increase in profit margins and product quality, a win-win for everyone.

Consumer Demand and Circular Economy Alignment

Meeting Eco-Conscious Shoppers' Expectations

Buyers these days want to live a green life style and value our environment. A poll finds that more than 75% of consumers are ready to pay extra for green goods. One consumer trend which is being seen in a lot of different ways, is the move towards a focus on sustainability, making it increasingly important for brands to be seen as eco-friendly as they can, and they need to do this to build trust and retain loyalty with customers. By adding sustainability to their marketing techniques, companies can let environmentally aware consumers know how much they are committed to a better world, increasing those emotions and warranting an increased slice of the market pie.

Refill Systems Compatible with Existing Containers

Time after time, we realize that 'refill systems' that are compatibleplug_n_play with our own containers are becoming indispensable for sustainable behaviour. With such systems, unnecessary waste created by disposable packaging can be reduced, and environmental issues can be quickly resolved. Statistics show that refilling consumers can reduce their plastic consumption by as much as 40%. The reduced cost of packaging also helps the manufacturers create a better customer loyalty through sustainable options which results in a win-win to both company and consumer.

Brand Storytelling Through Sustainable Packaging

Brand storytelling is a growing business technique that's helping companies do just that by weaving their sustainability initiatives into their master narrative. Companies can appear more accessible, and relatable, by revealing more about their sustainable packaging policies. It has been found that companies that focus on sustainability can gain market share and brand equity. Telling these stories of sustainability through social media and other communication channels not only raises brand profile, but also helps promote consumer engagement so is an important strategy in today’s market context.

Future-Proofing Sprayer Technology

Smart Sensors for Product Usage Tracking

The addition of smart sensors on trigger sprayers has the potential to become transformative in product usage monitoring. These sensors deliver analytics in real time, which can provide manufactures with valuable information on how consumers use the appliances. This kind of data informs the development process, showing patterns and trends in usage. Also, it's easier to use with improved resource utilization and minimal waste. By knowing how their products are being used, manufacturers can also leverage predictive analytics to manage stock and match supply to market demand, maximizing efficiency and customer satisfaction.

Chemical-Resistant Formulas for Longevity

Chemically resistant formulations are important, to ensure the durability of plastic trigger sprayers particularly in like environments. This chemistry permits products to withstand extreme environments, vastly reducing replacement costs and inhibiting disposal in a landfill. The product that can handle wear and tear is also sustainable by reducing turnover. In addition, brands can grow their market share by creating hardy and resistant sprayers, in order to appeal to the desires of the consumer who now craves dependability and longevity in buying.

Partnerships with Recycling Infrastructure Providers

Forming partnerships with recycling infrastructure enablers is essential to improve the recyclability of plastic trigger sprayers. These partnerships can enable recycling systems that work well and create significant gains for the circular economy. Some businesses see a significant increase in the effectiveness of waste management when they form strong recycling partnerships. Through the development of these relationships, manufacturers will be able to bring new ideas and strategies to the fore while driving sustainable practices that will move the production process to one that is more environmentally friendly and boast them as sustainability leaders in their space.

FAQs

Why are multi-material dispensing systems difficult to recycle?

Multi-material dispensing systems are difficult to recycle because they are composed of various materials like plastic and metal, which complicates the recycling process and makes it less efficient.

How do mono-material designs improve recyclability?

Mono-material designs use only one type of plastic, streamlining recycling processes by eliminating contamination risks and increasing recovery rates.

What environmental advantages do all-plastic designs offer?

All-plastic designs remove metal contaminants, minimize recycling stream contamination, and reduce transportation emissions due to their lightweight nature.

In which industries are plastic trigger sprayers particularly beneficial?

Plastic trigger sprayers are beneficial in household cleaning, personal care, and agriculture for their environmental efficiency and precision in applications.

How are manufacturers making sprayer production more sustainable?

Manufacturers are moving towards sustainable production by using bio-based polymers, adopting energy-efficient molding techniques, and partnering with recycling infrastructure providers.

What role does consumer demand play in sustainable packaging?

Consumer demand for eco-friendly products drives brands to adopt sustainable practices, offering refill systems and using brand storytelling to communicate sustainability efforts.

Table of Contents

- How All-Plastic Trigger Sprayers Combat Packaging Waste

- Environmental Advantages of Plastic-Only Construction

- Key Industries Benefiting from Plastic Trigger Sprayers

- Manufacturing Innovations Driving Sustainability

- Consumer Demand and Circular Economy Alignment

- Future-Proofing Sprayer Technology

-

FAQs

- Why are multi-material dispensing systems difficult to recycle?

- How do mono-material designs improve recyclability?

- What environmental advantages do all-plastic designs offer?

- In which industries are plastic trigger sprayers particularly beneficial?

- How are manufacturers making sprayer production more sustainable?

- What role does consumer demand play in sustainable packaging?