Essential Guide to Roll On Bottle Selection for Product Success

Choosing the perfect roll on bottle for your brand can make the difference between a successful product launch and a mediocre market performance. Whether you're developing a new essential oil blend, perfume, or therapeutic solution, the roll on bottle you select will significantly impact user experience, product preservation, and brand perception. This comprehensive guide will walk you through everything you need to know about selecting the ideal roll on bottle that aligns with your brand vision and product requirements.

Understanding Roll On Bottle Materials and Their Benefits

Glass Roll On Bottle Options

Glass roll on bottles represent the premium choice in packaging solutions, offering superior chemical resistance and product preservation capabilities. Clear glass allows customers to see the product level, while amber and cobalt blue variations provide UV protection for light-sensitive formulations. High-quality glass bottles maintain product integrity and convey a sense of luxury that resonates with discerning consumers.

Premium glass roll on bottles often feature precision-engineered roller balls that ensure smooth, consistent product application. The weight and feel of glass containers also contribute to a more luxurious user experience, making them particularly suitable for high-end skincare products and essential oil blends.

Plastic Roll On Container Solutions

Modern plastic roll on bottles offer versatility and practicality for various applications. These lightweight containers are ideal for travel-friendly products and situations where breakage concerns exist. Advanced polymer technologies have produced plastic bottles that maintain product stability while providing cost-effective packaging solutions.

Recyclable plastic options have gained popularity among environmentally conscious brands, allowing companies to align with sustainability initiatives while maintaining product quality. These containers often feature special treatments to prevent product interaction and maintain formula integrity throughout the product's shelf life.

Size and Capacity Considerations

Standard Roll On Dimensions

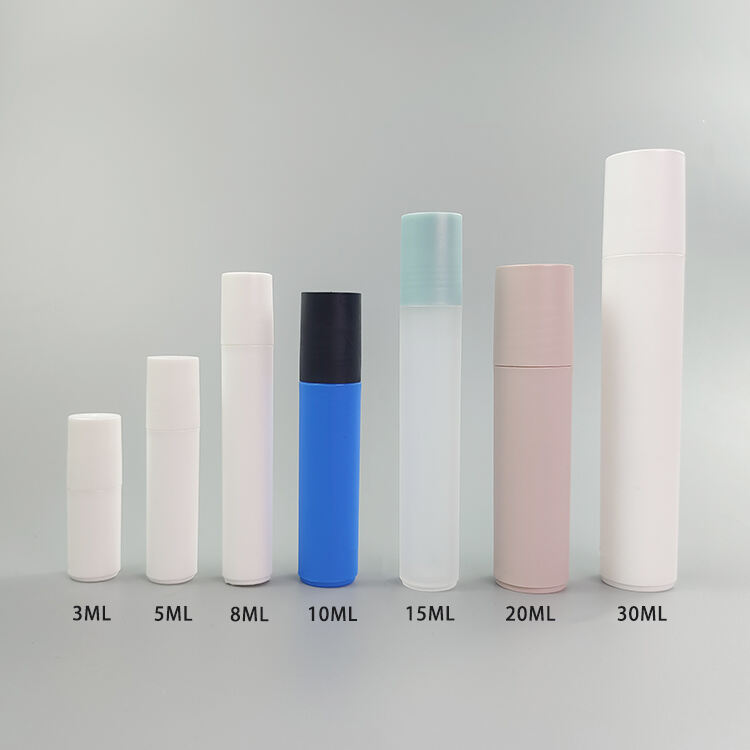

The most common roll on bottle sizes range from 5ml to 15ml for personal care products and essential oils. These sizes balance portability with sufficient product quantity for regular use. The 10ml size has emerged as an industry standard, offering enough product for several weeks of use while maintaining a compact form factor.

When selecting bottle dimensions, consider your target market's usage patterns and price point expectations. Premium products often come in smaller sizes to justify higher price points, while daily-use items may require larger capacities to provide value for money.

Custom Sizing Options

Custom roll on bottle sizes can help your brand stand out in the marketplace. Some manufacturers offer unique dimensions that can become signature elements of your product line. Consider how different sizes might serve various market segments or special product applications.

Working with bottle manufacturers who offer customization options allows you to create distinctive packaging that reinforces your brand identity while meeting specific product requirements. This approach can lead to improved brand recognition and customer loyalty.

Roller Ball Mechanisms and Quality Features

Metal Ball Types and Benefits

Stainless steel roller balls provide excellent durability and a cooling sensation during application. These premium components resist corrosion and maintain smooth operation throughout the product's life cycle. The weight and feel of metal balls often contribute to a more luxurious user experience.

Different metal ball sizes can affect product dispensing rates and application precision. Larger balls typically provide faster product release, while smaller ones offer more controlled application for concentrated formulations.

Plastic Roller Technology

Advanced plastic roller balls offer cost-effective solutions without compromising performance. Modern materials provide smooth rolling action and chemical resistance comparable to metal alternatives. These components are particularly suitable for products that might react with metal surfaces.

Some plastic rollers feature specialized designs that enhance product control and prevent leakage during transport. The latest innovations in plastic roller technology have significantly improved the user experience while maintaining competitive pricing.

Closure Systems and Safety Features

Secure Cap Designs

The right closure system ensures product safety and prevents leakage during storage and transport. Thread designs and cap materials play crucial roles in maintaining an airtight seal. Modern roll on bottles often feature child-resistant options for products requiring additional safety measures.

Some caps incorporate tamper-evident features that help maintain product integrity and build consumer trust. Advanced closure systems may also include special venting mechanisms to prevent pressure buildup while maintaining product freshness.

Travel-Safe Features

For products intended for travel use, additional security features become essential. Some roll on bottles include secondary seals or locking mechanisms that prevent accidental opening during transit. These features can significantly reduce returns and customer complaints related to leakage.

Consider how your product will be transported and stored when selecting closure systems. The right combination of cap design and sealing mechanism can protect your product while enhancing user convenience.

Frequently Asked Questions

What is the best roll on bottle material for essential oils?

Glass roll on bottles, particularly amber or cobalt blue varieties, are ideal for essential oils as they provide UV protection and chemical resistance. These materials help maintain product potency and prevent degradation from light exposure.

How do I choose the right roller ball size for my product?

Consider your product's viscosity and desired application rate. Larger balls (5-8mm) work well for thinner liquids and broader application areas, while smaller balls (3-5mm) offer more precise control for concentrated formulas.

Can roll on bottles be recycled?

Many roll on bottles are recyclable, particularly those made from glass or specific types of plastic. Look for bottles with recycling codes and consider using eco-friendly materials that align with sustainability goals while maintaining product integrity.

What security features should I look for in roll on bottle closures?

Key security features include tamper-evident seals, child-resistant caps, and secure threading systems. For products requiring additional protection, consider bottles with secondary sealing mechanisms or special locking features to prevent leakage during transport.